Engineering Services: DCS, PLC, SCADA, VAPT in OT and IT Environment

Our engineering services for Distributed Control Systems (DCS), Programmable Logic Controllers (PLC), and Supervisory Control and Data Acquisition (SCADA) are designed to support the full lifecycle of your industrial automation projects on multiple domain like Power, Oil & Gas, Pulp & Paper, Marine, Metal & Mining, Sugar Industries. From hardware engineering and software development to commissioning and beyond, we offer comprehensive solutions that ensure your systems operate efficiently, reliably, and securely.

In today’s rapidly evolving technological landscape, our engineering services stand at the forefront of DCS (Distributed Control Systems), PLC (Programmable Logic Controllers), SCADA (Supervisory Control and Data Acquisition), and Vulnerability Assessment and Penetration Testing (VAPT) in both Operational Technology (OT) and Information Technology (IT) environments. We specialize in providing comprehensive solutions that integrate advanced automation and cybersecurity measures, ensuring the seamless operation of critical infrastructure.

Our expertise in DCS allows us to design and implement robust control systems tailored to the unique needs of various industries, including power generation, oil and gas, and manufacturing. By optimizing control processes, we help organizations enhance efficiency, reduce operational costs, and improve safety. Similarly, our PLC services focus on programming and configuring automation systems, empowering clients to automate their processes with precision and reliability.

In the realm of SCADA, we deliver sophisticated monitoring and control solutions that provide real-time insights into industrial operations. Our SCADA systems facilitate data acquisition and remote management, enabling organizations to respond swiftly to any anomalies and ensure smooth operations. This is vital in maintaining the integrity of production processes and minimizing downtime.

Additionally, our VAPT services are designed to safeguard both OT and IT environments against emerging cybersecurity threats. By conducting thorough assessments and penetration tests, we identify vulnerabilities within systems and provide actionable insights to fortify defenses. This proactive approach to cybersecurity is essential for protecting critical infrastructure from potential attacks.

Combining our deep technical knowledge with industry best practices, we ensure that our engineering services not only meet regulatory compliance but also align with the latest technological advancements. Our team of skilled engineers and cybersecurity experts is committed to delivering high-quality solutions that empower organizations to achieve their operational and security objectives effectively.

With a focus on innovation and excellence, our engineering services are designed to address the complex challenges of modern industrial environments. We are dedicated to helping our clients navigate the intricacies of OT and IT integration, ensuring a resilient and secure infrastructure that supports their business goals.

1 – Hardware Engineering

Hardware engineering is the backbone of any automation system, and our expertise in this area ensures that your DCS, PLC, and SCADA systems are built on a solid foundation.

Our Hardware Engineering Services Include

System Design and Architecture

We design and develop customized hardware solutions tailored to your specific process requirements, ensuring optimal performance and scalability.

System design and architecture in Distributed Control Systems (DCS) is a critical aspect of modern industrial automation, enabling efficient monitoring and control of complex processes across various sectors. A well-structured DCS design ensures optimal performance, reliability, and scalability while addressing the unique requirements of each application. The architecture encompasses various components, including controllers, communication networks, input/output (I/O) devices, and human-machine interfaces (HMIs), all integrated to facilitate seamless operations.

At the core of a DCS architecture lies the central control system, typically comprised of redundant controllers that enhance reliability and ensure continuous operation. These controllers execute control algorithms, manage data processing, and communicate with field devices to maintain optimal process conditions. The design must consider factors such as system redundancy, fault tolerance, and real-time data processing to mitigate risks and ensure operational stability.

The communication network within a DCS architecture plays a vital role in connecting field devices to the control system. Utilizing industrial protocols, such as Modbus, Profibus, or Ethernet/IP, the network must support high-speed data transfer while ensuring secure communication between devices. Proper network design helps reduce latency and enhances the overall responsiveness of the system.

Input/output devices, including sensors and actuators, are crucial for data acquisition and process control. In a DCS, the design should facilitate easy integration of these devices, allowing for real-time monitoring and precise control over the production processes. Effective I/O configuration contributes to improved data accuracy and process efficiency.

Human-machine interfaces (HMIs) are essential for operators to interact with the DCS, providing visualizations of process data, alarms, and control options. The design of HMIs should prioritize usability and clarity, enabling operators to make informed decisions quickly. An intuitive interface fosters better situational awareness, reducing the likelihood of errors during operation.

A successful DCS design also incorporates considerations for maintenance and support. Modular architecture allows for easier upgrades and troubleshooting, minimizing downtime and operational disruptions. By implementing best practices in system design and architecture, organizations can achieve higher productivity, safety, and compliance with industry standards.

In summary, effective system design and architecture in DCS are vital for managing complex industrial processes. By focusing on reliability, communication, and user experience, companies can create robust systems that optimize performance and enhance operational efficiency.

Panel Design and Fabrication

Our team creates detailed designs for control panels, including wiring diagrams, layout configurations, and component selection. We also oversee the fabrication of panels to meet exacting industry standards.

In the realm of industrial automation, the design and fabrication of control panels are critical for ensuring the efficient operation of DCS (Distributed Control Systems), PLC (Programmable Logic Controllers), and SCADA (Supervisory Control and Data Acquisition) systems. Our company specializes in delivering high-quality panel design and fabrication services tailored to meet the unique needs of various industries, including manufacturing, power generation, and water treatment.

Our experienced engineering team utilizes advanced design software to create detailed schematics and layouts that optimize space and enhance functionality. Each control panel is meticulously designed to accommodate specific project requirements while ensuring compliance with industry standards and regulations. By integrating DCS, PLC, and SCADA technologies, we provide robust control solutions that streamline operations and improve system reliability.

During the fabrication process, we utilize high-grade materials and state-of-the-art manufacturing techniques to produce durable and efficient control panels. Our skilled technicians work diligently to ensure that every component is installed with precision, ensuring optimal performance and safety. Rigorous quality control measures are implemented throughout the fabrication process to guarantee that each panel meets our stringent quality standards.

We understand that effective control systems require seamless integration and communication between various components. Our control panels are designed to facilitate smooth interoperability among DCS, PLC, and SCADA systems, allowing for real-time monitoring and control of critical processes. This integration enhances operational visibility and helps our clients make informed decisions.

Moreover, our commitment to customer satisfaction drives us to provide personalized support throughout the entire project lifecycle, from initial consultation and design to fabrication and installation. We collaborate closely with our clients to understand their specific needs and challenges, ensuring that our solutions are not only effective but also align with their operational goals.

Our panel design and fabrication services for DCS, PLC, and SCADA systems combine innovation, quality, and expertise to deliver high-performance control solutions. By choosing our services, clients can trust in our ability to enhance their automation processes and drive operational excellence.

Field Instrumentation Integration

We handle the selection, installation, and integration of field instruments, sensors, actuators, and other hardware components, ensuring seamless communication with DCS, PLC, and SCADA systems.

Field instrumentation integration is a critical component of modern industrial automation, enabling seamless communication and control between various devices and systems in environments utilizing Distributed Control Systems (DCS), Programmable Logic Controllers (PLC), and Supervisory Control and Data Acquisition (SCADA) systems. As industries continue to embrace advanced technologies, the integration of field instruments plays a pivotal role in optimizing operational efficiency, enhancing data accuracy, and ensuring reliable process control.

In the context of DCS, field instrumentation serves as the backbone for real-time monitoring and control of complex processes. These instruments—such as sensors, transmitters, and actuators—gather essential data on temperature, pressure, flow, and other critical parameters. This data is then transmitted to the DCS for analysis and decision-making, allowing operators to maintain optimal operating conditions and respond swiftly to any deviations.

Similarly, PLC systems rely heavily on field instrumentation for executing automated processes in manufacturing and production settings. By integrating various sensors and control devices, PLCs can execute precise control commands based on real-time feedback, ensuring that machines operate smoothly and efficiently. This capability not only improves productivity but also enhances safety by reducing the risk of human error in operations.

SCADA systems further extend the functionality of field instrumentation by enabling remote monitoring and control across large geographical areas. By integrating field devices into a centralized SCADA framework, operators can visualize real-time data, generate historical reports, and analyze trends from multiple locations. This holistic view of operations empowers organizations to make informed decisions, optimize resource allocation, and respond promptly to operational issues.

Effective integration of field instrumentation in DCS, PLC, and SCADA environments necessitates a thorough understanding of communication protocols, wiring, and configuration techniques. Utilizing standardized protocols, such as Modbus, Profibus, or Ethernet/IP, facilitates interoperability between devices from different manufacturers, enhancing flexibility and scalability in automation systems.

As industries face increasing demands for efficiency and reliability, the integration of field instrumentation within automation frameworks is more important than ever. By leveraging advanced technologies and best practices in instrumentation integration, organizations can achieve higher levels of performance, safety, and compliance in their operations. Ultimately, this integration not only drives operational excellence but also lays the foundation for future innovations in the field of industrial automation.

Network Design and Implementation

We design and implement robust and secure networks that enable reliable data transmission and communication between controllers, HMIs, and remote devices.

In today’s industrial landscape, effective network design and implementation are crucial for the seamless operation of Distributed Control Systems (DCS), Programmable Logic Controllers (PLC), and Supervisory Control and Data Acquisition (SCADA) systems. As industries increasingly rely on interconnected devices for monitoring and controlling processes, a well-structured network ensures reliable communication, data integrity, and operational efficiency.

Our approach to network design focuses on creating robust architectures that support the unique requirements of DCS, PLC, and SCADA applications. We emphasize the importance of selecting the right protocols, hardware, and topologies to facilitate optimal data flow and system performance. By leveraging industry best practices, we aim to minimize latency and enhance the reliability of critical systems.

Implementation involves not only the physical deployment of network infrastructure but also the integration of cybersecurity measures to protect against potential threats. Our team of experts ensures that all network components are configured correctly, enabling secure and efficient communication between devices. This includes establishing firewalls, intrusion detection systems, and secure access controls to safeguard sensitive data.

In addition, we provide comprehensive testing and validation of network configurations to ensure they meet the operational needs of DCS, PLC, and SCADA systems. By simulating real-world scenarios, we can identify potential vulnerabilities and address them proactively. Our commitment to quality assurance guarantees that our clients can rely on their networks for uninterrupted operations.

Ultimately, our goal is to empower organizations with the knowledge and tools necessary for successful network design and implementation. By focusing on scalability, security, and performance, we help businesses adapt to the evolving technological landscape and maintain a competitive edge in their respective industries.

2 – Software Engineering: Graphics and Logic Development

Software engineering is crucial for translating hardware capabilities into functional, automated processes. Our team excels in creating intuitive graphics from P&IDS and robust logic programs from SAMA Logic and Control narratives that enhance system operability and efficiency.

In the evolving landscape of industrial automation, software engineering plays a crucial role in enhancing the functionality and efficiency of systems such as Distributed Control Systems (DCS), Programmable Logic Controllers (PLC), and Supervisory Control and Data Acquisition (SCADA). As industries strive for increased productivity and reliability, the integration of graphics and logic development in software engineering becomes paramount. This involves creating intuitive graphical interfaces and robust logical frameworks that facilitate seamless monitoring and control of complex industrial processes.

Graphics development focuses on designing user-friendly interfaces that allow operators to visualize and interact with system data effectively. By utilizing advanced visualization techniques, engineers can create dynamic dashboards that display real-time information, trends, and alerts, enabling quick decision-making and enhancing operational efficiency.

This graphical representation simplifies the management of intricate processes, making it easier for personnel to understand system performance and respond to potential issues swiftly.

On the other hand, logic development is fundamental in programming PLCs and configuring DCS and SCADA systems. Engineers apply logical constructs to design control algorithms that govern automated processes, ensuring that systems operate smoothly and safely. Through rigorous logic programming, they can implement complex control strategies that adapt to varying operational conditions, thereby maximizing system uptime and minimizing risks.

Moreover, the synergy between graphics and logic development is essential for effective system integration. A well-designed graphical interface combined with robust logic ensures that operators have the necessary tools to manage operations efficiently. This holistic approach to software engineering not only enhances user experience but also contributes to the overall reliability and security of industrial automation systems.

As industries increasingly adopt digital transformation, the demand for skilled software engineers proficient in graphics and logic development continues to grow. These professionals are vital in bridging the gap between technology and operational excellence, ensuring that DCS, PLC, and SCADA systems meet the evolving needs of modern industrial environments. By prioritizing innovative software engineering practices, organizations can drive improvements in process control, data management, and operational insights, positioning themselves for success in a competitive market.

Our Software Engineering Services Include

Control Logic Development

We develop precise and reliable control logic for DCS, PLC, and SCADA systems, using programming languages like ladder logic, function block, and structured text based on multiple input document like Control Narratives, SAMA document and Cause & Effect Narrative. Our logic designs are tailored to meet your specific process control requirements.

Control logic development is a critical aspect of automation in industrial settings, encompassing systems such as DCS (Distributed Control Systems), PLC (Programmable Logic Controllers), and SCADA (Supervisory Control and Data Acquisition). This process involves designing, implementing, and optimizing control strategies that govern the operation of machinery and processes, ensuring efficiency, safety, and reliability.

In a DCS environment, control logic development focuses on managing complex processes through a decentralized architecture. It enables the integration of various control elements across multiple locations, allowing for real-time monitoring and adjustment of operations. This level of control is essential in industries like power generation and chemical processing, where precise coordination of equipment is vital for optimal performance.

For PLC systems, control logic development often involves programming languages such as Ladder Logic, Function Block Diagram, and Structured Text. These languages provide the necessary tools to create algorithms that dictate how inputs from sensors are transformed into outputs for actuators. PLCs are widely used in manufacturing and assembly lines, where quick responses to changing conditions are crucial.

SCADA systems complement both DCS and PLC by providing a comprehensive overview of the entire process. Control logic in SCADA focuses on data acquisition, visualization, and remote control of industrial processes. It allows operators to monitor system performance, identify anomalies, and make informed decisions based on real-time data analysis. This holistic approach enhances operational awareness and facilitates timely interventions when issues arise.

Overall, effective control logic development is essential for optimizing automation systems across various industries. By leveraging DCS, PLC, and SCADA technologies, organizations can enhance process control, improve operational efficiency, and ensure the safety and reliability of their industrial operations. As the complexity of industrial processes continues to grow, mastering control logic development becomes increasingly vital for professionals in the automation field.

HMI/SCADA Graphics Development

We create user-friendly HMI and SCADA interfaces with the help of P&IDs for process that provide operators with real-time visibility and control over the entire process. Our graphics are designed for clarity and ease of use, facilitating quick decision-making and minimizing operational risks.

HMI (Human-Machine Interface) and SCADA (Supervisory Control and Data Acquisition) graphics development plays a crucial role in modern industrial automation. As industries increasingly rely on complex DCS (Distributed Control Systems), PLC (Programmable Logic Controllers), and SCADA systems, effective graphics development becomes essential for real-time monitoring and control of processes.

The primary goal of HMI/SCADA graphics is to provide operators with intuitive, user-friendly interfaces that enhance situational awareness and streamline decision-making. By visualizing critical data through graphical representations, operators can easily interpret system statuses, monitor performance metrics, and identify anomalies at a glance. This is particularly important in environments where rapid response is vital to maintaining safety and efficiency.

In DCS environments, graphics development focuses on creating detailed representations of processes, enabling operators to visualize everything from simple tank levels to complex multi-variable interactions. The graphical interface allows for the seamless integration of control commands, ensuring that operators can make adjustments swiftly and accurately.

For PLC applications, effective HMI graphics enable technicians to monitor and control automated machinery with precision. Graphics development for PLC systems emphasizes real-time data visualization, facilitating quick diagnostics and troubleshooting. This empowers operators to maintain optimal performance and minimize downtime in production processes.

In SCADA systems, graphics play a pivotal role in providing an overview of geographically distributed assets. Well-designed SCADA graphics can present data from multiple sites in a consolidated view, allowing operators to manage extensive operations efficiently. Customizable dashboards provide insights into performance indicators, alarms, and historical data trends, essential for informed decision-making.

As industries evolve, so do the requirements for HMI/SCADA graphics development. It is imperative for graphic designers and engineers to stay abreast of the latest technologies and design principles, ensuring that their interfaces are not only visually appealing but also functionally robust. By incorporating best practices in usability and accessibility, organizations can enhance their operators’ experience and improve overall system reliability.

Effective HMI/SCADA graphics development is integral to the success of DCS, PLC, and SCADA systems. It enhances operational efficiency, promotes safety, and supports informed decision-making in complex industrial environments. Investing in skilled graphics development can yield significant returns, driving productivity and ensuring seamless operations in today’s fast-paced automation landscape.

Alarm & Information Management AIMS

We develop and configure comprehensive alarm systems within DCS, PLC, and SCADA platforms, ensuring that critical process conditions are promptly flagged and addressed.

Alarm & Information Management Systems (AIMS) play a crucial role in enhancing operational efficiency and safety within DCS (Distributed Control Systems), PLC (Programmable Logic Controllers), and SCADA (Supervisory Control and Data Acquisition) environments. These systems are designed to effectively manage alarms and information flow, ensuring that operators can quickly respond to critical events and maintain optimal performance in industrial processes.

In modern control environments, the volume of alarms can overwhelm operators, leading to alarm fatigue and potentially dangerous situations. AIMS addresses this challenge by implementing structured alarm management practices that prioritize alerts based on urgency and relevance. By categorizing alarms and providing clear information, AIMS enables operators to focus on critical issues without being distracted by unnecessary notifications.

The integration of AIMS within DCS environments ensures that alarm systems are optimized for the specific processes being monitored. This includes setting appropriate thresholds, reducing nuisance alarms, and providing context around alarms to enhance operator decision-making. In PLC systems, AIMS can be tailored to control-specific applications, improving the response time and effectiveness of operators when addressing alarms.

SCADA systems also benefit significantly from AIMS, as they often monitor vast geographical areas and complex processes. AIMS provides a centralized platform for managing alarms across multiple locations, facilitating real-time data analysis and reporting. This enables operators to visualize alarm trends, evaluate system performance, and implement improvements in alarm management strategies.

Moreover, AIMS supports compliance with industry standards and regulations by ensuring that alarm systems are maintained, reviewed, and optimized regularly. This continuous improvement approach helps organizations enhance safety, reduce operational risks, and improve overall process reliability.

Alarm & Information Management Systems are essential for effectively managing alarms in DCS, PLC, and SCADA environments. By streamlining alarm processes and providing valuable insights, AIMS enhances operator awareness, promotes safety, and drives operational excellence in industrial settings.

Historian

We provide Data Collection, Data Storage, Data Analysis, Data Reporting, Asset management, ERP, Optimization tools, various user on intranet.

A Historian is a crucial component in modern industrial automation systems, particularly in environments utilizing Distributed Control Systems (DCS), Programmable Logic Controllers (PLC), and Supervisory Control and Data Acquisition (SCADA) systems. It serves as a specialized database designed to collect, store, and manage time-series data generated by various processes and equipment. By capturing vast amounts of operational data, a Historian enables organizations to monitor performance, analyze trends, and improve decision-making.

In a DCS environment, the Historian plays a vital role in ensuring data integrity and accessibility. It collects information from multiple sensors, controllers, and processes, allowing operators to visualize historical data alongside real-time metrics. This integration provides insights into process efficiencies, equipment performance, and overall system health, facilitating proactive maintenance and operational optimization.

For PLC systems, a Historian allows for detailed tracking of automation processes, providing valuable data on production cycles, machine states, and fault occurrences. By analyzing this information, organizations can identify patterns, reduce downtime, and implement corrective actions to enhance overall productivity.

In SCADA applications, the Historian becomes the backbone for data logging, reporting, and analytics. It gathers data from remote sites and field devices, enabling centralized monitoring and control. The ability to archive historical data aids in regulatory compliance, as organizations can easily retrieve and present operational information when required.

The use of a Historian enhances the capability to perform advanced analytics, including predictive maintenance and performance benchmarking. By utilizing historical data, organizations can develop models that forecast potential issues and streamline their operations based on empirical evidence. This data-driven approach fosters continuous improvement and innovation within the industry.

Moreover, modern Historian solutions offer advanced features such as cloud integration, real-time dashboards, and mobile access. These functionalities empower engineers and operators to access critical information anytime, anywhere, thus enhancing collaboration and responsiveness in operational decision-making.

In summary, a Historian is an essential tool in DCS, PLC, and SCADA systems, transforming raw data into actionable insights. Its role in data collection, storage, and analysis is pivotal for organizations striving for efficiency, reliability, and competitiveness in today’s industrial landscape.

Simulation and Testing

Before deployment, we rigorously test all software components in simulated environments, ensuring that logic and graphics perform as expected under various process conditions.

Simulation and testing play a crucial role in the development and implementation of Distributed Control Systems (DCS), Programmable Logic Controllers (PLC), and Supervisory Control and Data Acquisition (SCADA) systems. These processes ensure that systems operate correctly and efficiently before they are deployed in real-world environments. By utilizing simulation tools, engineers can create virtual models of control systems, enabling them to visualize and analyze system behavior under various conditions.

In DCS, simulation allows for the testing of control strategies and system responses to changes in input parameters. This helps identify potential issues and optimize control algorithms, ensuring the system can handle expected operational scenarios. Furthermore, simulation in DCS facilitates training for operators, allowing them to gain experience and confidence in managing the control system without risking actual production processes.

For PLC systems, simulation software provides a platform to develop, test, and debug ladder logic programs or other programming languages. This not only accelerates the development process but also minimizes the risk of errors that could lead to costly downtime or safety hazards. Engineers can simulate I/O interactions, program execution, and fault conditions, ensuring that the PLC will perform as intended when deployed in a live environment.

In the context of SCADA systems, simulation enables operators and engineers to monitor and control processes in a virtual setting. By simulating data acquisition and real-time monitoring, users can assess the effectiveness of the SCADA system in managing critical infrastructure. This allows for thorough testing of alarm systems, data logging, and visualization interfaces, ensuring that all components function seamlessly together.

Overall, simulation and testing in DCS, PLC, and SCADA systems are vital for enhancing system reliability, performance, and safety. They enable engineers to validate their designs, train operators, and prepare for real-world operations with confidence. By investing in simulation technologies, organizations can reduce costs, improve system robustness, and ensure optimal performance in complex industrial environments.

3 – Commissioning Activities

Site commissioning activities are critical steps in the successful deployment and operation of Distributed Control Systems (DCS), Programmable Logic Controllers (PLC), and Supervisory Control and Data Acquisition (SCADA) systems. These activities ensure that all components of a control system function correctly and efficiently, ultimately enhancing operational reliability and safety. The commissioning process involves systematic testing, calibration, and verification of the installed systems, aligning them with design specifications and industry standards.

The first phase of site commissioning typically includes a thorough review of the installation against project documentation. This entails verifying that all hardware and software components are installed correctly and conform to the required specifications. Any discrepancies identified at this stage must be addressed before moving forward, ensuring a solid foundation for the commissioning process.

Once the initial checks are complete, the focus shifts to functional testing of the DCS, PLC, and SCADA systems. This involves simulating various operational scenarios to validate the performance of the systems under different conditions. Test cases are meticulously executed to ensure that each component interacts seamlessly with others, enabling effective control and monitoring of industrial processes.

During this phase, a crucial aspect of site commissioning is the calibration of instruments and sensors. Accurate measurements are vital for the systems to respond correctly to changing process parameters. This step not only enhances the reliability of the system but also ensures compliance with regulatory and safety standards.

Another essential part of site commissioning is the integration of the control systems with existing infrastructure. This integration process involves aligning the new systems with legacy equipment, ensuring compatibility and communication between all devices. Proper integration is vital for the efficient exchange of data and control signals, which ultimately supports enhanced decision-making capabilities in industrial operations.

Training personnel on the new systems is also a key component of the commissioning process. Operators and maintenance staff must be familiar with the functionalities and features of the DCS, PLC, and SCADA systems to ensure smooth operations. Comprehensive training sessions cover system operation, troubleshooting, and maintenance, empowering the team to effectively manage the systems post-commissioning.

Finally, after successful commissioning activities, a detailed documentation process captures all findings, test results, and configurations. This documentation serves as a valuable resource for future maintenance and troubleshooting efforts, ensuring that any issues can be swiftly addressed. Overall, site commissioning activities play a pivotal role in ensuring that DCS, PLC, and SCADA systems are fully operational, safe, and ready to meet the demands of modern industrial processes.

Our Commissioning Services Include

Pre-Commissioning Checks

We conduct detailed pre-commissioning checks, including wiring verification, loop testing, and system power-up, to ensure that all hardware components are installed correctly and functioning as intended.

Pre-commissioning checks are a critical phase in the deployment of DCS (Distributed Control Systems), PLC (Programmable Logic Controllers), and SCADA (Supervisory Control and Data Acquisition) systems. These checks ensure that all components are properly installed, functional, and ready for the commissioning phase. By conducting thorough pre-commissioning inspections, organizations can mitigate risks, enhance safety, and ensure the integrity of the entire automation system.

The pre-commissioning process typically begins with a detailed review of design documentation, including system specifications, wiring diagrams, and functional descriptions. This step is essential to verify that all components meet the project’s requirements and are correctly aligned with engineering standards. Any discrepancies identified during this review can be addressed before the installation progresses, saving time and resources later in the project.

Following the documentation review, physical inspections of the equipment are conducted. This includes checking the installation quality of control panels, wiring integrity, and the proper mounting of field devices. These inspections help ensure that all components are securely installed and conform to safety regulations and industry standards.

Next, functional checks are performed on individual components and subsystems. This includes testing PLC I/O modules, DCS controllers, and SCADA interfaces to confirm that they operate as intended. By validating each component’s functionality at this stage, potential issues can be identified and rectified before full system integration.

Additionally, communication tests are conducted to ensure seamless data exchange between devices and the central control system. This includes verifying network configurations, signal integrity, and addressing any potential communication errors. Robust communication pathways are vital for system reliability and performance.

Finally, documentation of all pre-commissioning checks is crucial for future reference and compliance purposes. Detailed records help track issues, resolutions, and modifications made during this phase, providing valuable insights for the commissioning team. This documentation also supports ongoing maintenance and troubleshooting efforts.

Pre-commissioning checks for DCS, PLC, and SCADA systems play a vital role in ensuring the successful deployment of automation solutions. By rigorously verifying installations and functionalities, organizations can enhance system reliability, safety, and overall operational efficiency, paving the way for a smooth commissioning process.

Software Commissioning

Our engineers load and test control logic and HMI/SCADA configurations in the actual plant environment, making necessary adjustments to optimize system performance.

Software commissioning is a critical phase in the deployment of Distributed Control Systems (DCS), Programmable Logic Controllers (PLC), and Supervisory Control and Data Acquisition (SCADA) systems. This process involves the development, testing, and validation of control logic and graphical interfaces that are essential for efficient plant operations. It ensures that the automation systems function correctly and meet the specific requirements of industrial processes.

During the commissioning process, control logic is meticulously designed and programmed to reflect the operational needs of the facility. This includes creating algorithms that dictate how the system responds to various inputs, ensuring safety, reliability, and optimal performance. Properly commissioned logic minimizes the risk of operational errors and enhances the overall efficiency of the system.

In addition to control logic, graphics play a vital role in the commissioning process. User interfaces must be intuitive and informative, providing operators with real-time data and insights into system performance. Effective graphics help in monitoring processes, diagnosing issues, and making informed decisions quickly. The commissioning team must ensure that these graphical elements are not only functional but also user-friendly.

Thorough testing is essential during software commissioning. Each logic block and graphical element is subjected to rigorous validation to confirm that they perform as intended under various operational scenarios. This step is crucial in identifying and rectifying potential issues before the system goes live, thereby reducing downtime and enhancing safety.

Ultimately, successful software commissioning lays the foundation for a reliable and efficient control system. It integrates DCS, PLC, and SCADA components seamlessly, ensuring that all elements work together harmoniously. By investing time and expertise in this critical phase, organizations can achieve greater operational efficiency, safety, and compliance with industry standards.

System Integration

We ensure seamless integration of DCS, PLC, and SCADA systems with other plant equipment and enterprise systems, facilitating smooth data flow and process coordination.

System integration in industrial automation is a critical process that ensures various components of DCS (Distributed Control Systems), PLC (Programmable Logic Controllers), and SCADA (Supervisory Control and Data Acquisition) work seamlessly together. This integration allows for a unified approach to managing complex industrial processes, enhancing operational efficiency and reliability.

In a typical industrial environment, DCS serves as the backbone for process control, providing centralized monitoring and control over various operational parameters. By integrating DCS with PLC systems, organizations can achieve greater flexibility and scalability in their automation processes. PLCs, known for their robustness and real-time control capabilities, handle discrete control tasks while DCS manages the overall process, ensuring that operations run smoothly.

SCADA systems play a vital role in this integration by providing a comprehensive overview of system performance and status through graphical interfaces. They collect and analyze data from both DCS and PLC systems, enabling operators to make informed decisions based on real-time information. This synergy between DCS, PLC, and SCADA not only improves monitoring capabilities but also enhances response times to operational issues.

The successful integration of these systems requires expertise in various technologies, protocols, and standards. By leveraging advanced communication protocols and network architectures, system integrators can ensure that DCS, PLC, and SCADA components communicate effectively. This integration minimizes data silos and fosters a cohesive operational environment where information flows freely between systems.

Moreover, integrated systems enhance data visibility, allowing for better analysis and reporting. This capability is crucial for organizations seeking to optimize their processes, reduce downtime, and improve overall productivity. In addition, system integration lays the foundation for implementing advanced technologies such as IoT (Internet of Things) and AI (Artificial Intelligence), further driving innovation in industrial automation.

In conclusion, system integration in DCS, PLC, and SCADA is essential for achieving optimal performance in industrial operations. By harmonizing these components, organizations can enhance their operational capabilities, respond effectively to challenges, and position themselves for future growth in an increasingly competitive landscape.

On-Site Testing and Calibration

We perform on-site testing, calibration, and fine-tuning of control systems to ensure they meet specified performance criteria and industry standards.

On-site testing and calibration are critical components in the maintenance and optimization of Distributed Control Systems (DCS), Programmable Logic Controllers (PLC), and Supervisory Control and Data Acquisition (SCADA) systems. These processes ensure that industrial automation systems function accurately, reliably, and efficiently, minimizing the risk of operational failures. Proper testing and calibration help maintain the integrity of the data collected and the commands executed, which are vital for effective process control.

In DCS environments, on-site testing involves evaluating the performance of control loops, sensor readings, and actuators. This process ensures that the system responds correctly to changes in process variables, enabling operators to maintain optimal conditions. Calibration is equally essential, as it aligns the system’s output with the actual measurements, ensuring that all components work cohesively to control the processes effectively.

For PLC systems, on-site testing and calibration are crucial to validate the programming logic and ensure that the controllers operate as intended. This includes checking the functionality of inputs and outputs, verifying communication between devices, and ensuring that safety protocols are in place. Accurate calibration guarantees that PLCs execute commands with precision, thus enhancing the overall reliability of the system.

SCADA systems, which play a vital role in monitoring and controlling industrial processes, also require meticulous on-site testing and calibration. This involves assessing the accuracy of data acquisition from field devices and ensuring that the communication links between the SCADA software and the hardware are functioning correctly. Regular calibration of sensors and transmitters in a SCADA environment is essential for maintaining the accuracy of process monitoring and control.

Implementing a robust on-site testing and calibration strategy helps organizations identify and rectify potential issues before they escalate into significant problems. This proactive approach enhances system performance, reduces downtime, and ultimately leads to increased operational efficiency. By prioritizing on-site testing and calibration, companies can ensure that their DCS, PLC, and SCADA systems remain aligned with industry standards and regulatory requirements.

On-site testing and calibration are indispensable practices in the management of DCS, PLC, and SCADA systems. These activities not only uphold the integrity of industrial automation systems but also contribute to safer, more efficient operations. By investing in comprehensive testing and calibration services, organizations can safeguard their assets and optimize their processes, ultimately driving business success in an increasingly competitive landscape.

Operator Training and Handover

We provide comprehensive training to your operators and maintenance personnel, ensuring they are fully equipped to manage and maintain the new systems. We also offer detailed documentation and support during the handover process.

Operator training and handover in DCS (Distributed Control Systems), PLC (Programmable Logic Controllers), and SCADA (Supervisory Control and Data Acquisition) are critical components in ensuring the smooth operation of industrial processes. As industries become increasingly automated, the need for well-trained operators who can effectively manage and control these systems has never been greater. A comprehensive training program equips operators with the necessary skills to monitor, control, and troubleshoot complex systems, ensuring optimal performance and safety.

In a DCS environment, operators are responsible for overseeing multiple processes from a centralized control room. Effective training emphasizes not only the technical aspects of system operations but also the importance of understanding process dynamics and control strategies. Operators learn to interpret data, respond to alarms, and make informed decisions that enhance operational efficiency and safety.

Similarly, training for PLC systems focuses on programming, troubleshooting, and maintenance. Operators gain hands-on experience with various PLC programming languages, learning how to implement control logic for different applications. This foundational knowledge is essential for managing automation processes and ensuring that equipment operates smoothly.

SCADA training complements DCS and PLC instruction by teaching operators how to utilize SCADA systems for real-time monitoring and data analysis. Operators learn to visualize process data, generate reports, and respond to anomalies, enabling them to maintain optimal system performance. Understanding SCADA architecture and communication protocols is crucial for effective system management.

A structured handover process is equally vital, ensuring that knowledge transfer between outgoing and incoming operators occurs seamlessly. This process includes sharing operational insights, discussing ongoing issues, and highlighting any changes in procedures or system configurations. Effective handovers minimize disruptions and maintain continuity in operations.

By investing in comprehensive operator training and effective handover practices, organizations can enhance the competency of their workforce, reduce the risk of errors, and improve overall operational performance. In today’s fast-paced industrial landscape, a well-prepared team is essential for navigating the complexities of DCS, PLC, and SCADA systems, ensuring safety and efficiency in all operations.

Why Choose Our Engineering Services?

Expertise Across Industries

Our team has more than 20 years of extensive experience in deploying DCS, PLC, and SCADA systems across various industries, including oil and gas, power generation, pharmaceuticals, chemicals, and manufacturing.

When it comes to engineering services in DCS, PLC, and SCADA systems, our company stands out as a leader due to our unparalleled expertise across various industries. We understand that each sector—be it manufacturing, energy, water treatment, or pharmaceuticals—has unique challenges and requirements. Our team of seasoned professionals brings a wealth of knowledge and experience, enabling us to deliver solutions that are not only technically sound but also industry-specific.

Tailored Solutions

We understand that every project is unique. Our solutions are customized to meet the specific needs of your processes, ensuring maximum efficiency and reliability.

One of the core reasons to choose our services is our commitment to providing tailored solutions that address your specific needs. We recognize that a one-size-fits-all approach rarely works in complex industrial environments. Therefore, we take the time to assess your operational challenges, objectives, and existing infrastructure before crafting customized solutions that enhance efficiency, productivity, and safety.

Commitment to Quality

We adhere to the highest standards of quality in all our engineering activities, ensuring that your systems are not only functional but also durable and scalable.

Quality is the cornerstone of our engineering services. We adhere to stringent quality control measures and international standards, ensuring that every project we undertake meets the highest benchmarks of excellence. Our ISO 9001:2015 certification is a testament to our dedication to continuous improvement and customer satisfaction. We believe that delivering quality solutions is not just about meeting specifications but exceeding expectations.

End-to-End Service

From initial consultation and design to commissioning and ongoing support, we provide a complete suite of services, ensuring that your project is successful from start to finish.

we offer end-to-end services that encompass every stage of your project—from initial consultation and design to implementation and ongoing support. This holistic approach ensures that we are with you every step of the way, providing seamless integration and minimizing downtime. Our comprehensive services empower you to focus on your core operations while we handle the intricacies of DCS, PLC, and SCADA systems.

Choosing our engineering services means partnering with a company that prioritizes your success. Our commitment to innovation, tailored solutions, and quality assurance positions us as the ideal choice for organizations looking to enhance their automation and control systems. With us, you gain a trusted ally dedicated to delivering results that propel your business forward.

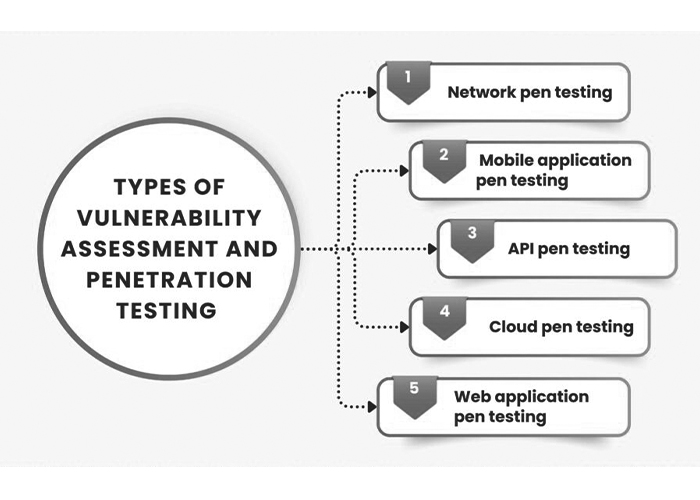

Vulnerability Assessment and Penetration Testing (VAPT) Services in OT & IT Environments

1 – Overview of VAPT in OT & IT:

Vulnerability Assessment and Penetration Testing (VAPT) are crucial for identifying and mitigating potential security risks in both OT (Operational Technology) and IT (Information Technology) environments. While IT focuses on the security of digital infrastructure, OT involves securing physical processes and machinery, making VAPT essential in safeguarding critical industries like manufacturing, energy, oil & gas, and utilities.

2 – VAPT in OT Environment:

Objective

Identify vulnerabilities in industrial control systems (ICS), SCADA, and DCS networks, ensuring operational continuity and safety.

Challenges

OT systems are often legacy systems with limited security features, making them more vulnerable to attacks. Additionally, downtime is costly, so testing must be conducted with minimal disruption.

Key Focus Areas

-

- Securing PLCs, RTUs, HMIs, and SCADA systems.

- Assessing the security of industrial protocols (Modbus, OPC, Profibus).

- Testing network segmentation and communication between IT and OT environments.

- Identifying physical security gaps in connected devices and critical infrastructure.

3 – VAPT in IT Environment:

Objective

Identify vulnerabilities in network infrastructure, applications, databases, and endpoints to ensure data confidentiality, integrity, and availability.

Key Focus Areas

-

- Network vulnerabilities (internal and external).

- Web and mobile application security testing.

- Assessing firewalls, intrusion detection/prevention systems (IDS/IPS), and endpoint protection.

- Cloud security assessments for IT assets hosted on cloud platforms.

4 – Benefits of VAPT in OT & IT

Risk Identification

VAPT helps identify vulnerabilities before attackers exploit them, preventing breaches in both OT and IT environments.

Improved Compliance

Many industries must comply with regulations like NERC CIP, IEC 62443, and ISO 27001. VAPT ensures adherence to cybersecurity standards.

Enhanced Security Posture

VAPT enhances the organization’s overall security by identifying weak points and enabling proactive defense strategies in both IT and OT infrastructure.

Minimized Downtime and Safety Risks

In OT environments, secure systems prevent operational disruptions, ensuring continuous and safe operations.

Threat Intelligence

Provides real-time insights into potential attack vectors and mitigates risks associated with emerging cyber threats in both IT and OT systems.

5. VAPT Process in OT & IT Environments

Discovery

Map and inventory all assets, systems, and networks in the IT and OT environment.

Vulnerability Assessment

Use automated tools and manual techniques to scan for known vulnerabilities and configuration issues.

Penetration Testing

Simulate real-world attacks to identify exploitable weaknesses and validate security defenses.

Reporting & Remediation

Provide detailed reports with prioritized vulnerabilities, along with recommendations for patching, mitigating, or remediating the identified risks.

6. Key Differences in VAPT for OT vs. IT

Downtime Sensitivity

OT systems often cannot afford downtime, requiring VAPT to be non-disruptive, unlike IT systems where controlled downtime is manageable.

Legacy Systems

OT environments often consist of legacy equipment not designed with cybersecurity in mind, whereas IT systems are regularly updated and patched.

Real-Time Impact

Cyberattacks on OT systems can cause physical harm or disrupt critical processes (e.g., power grids), whereas IT attacks typically compromise data security.